NEW 3D Printed HO and N Scale Goggle Valves

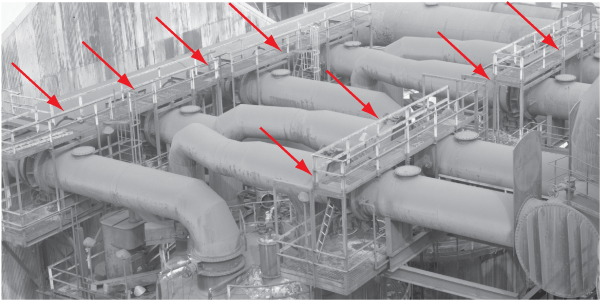

We now offer fully assembled HO scale goggle valves. These 3D printed parts are similarl to our laser cut models, but are fully assembled and have better details. The model will fit the Walthers Blast furnaces. The HO piper diameter is 0.81 inches.

We will still offer the laser cut kits are reduced price if you prefer a lower cost solution to adding detail to your blast furnace.

This laser cut multimedia kit is an HO scale model of a 72 inch goggle vale. It is designed to fit the stock pipes of the Walthers Corp HO Scale Blast Furnace kit. The kit provides all the parts to build a detailed replica of these important components of a blast furnace. Note that the pipes are not included in the kit.

For scratch builders, it can also be used with 0.75 inch Plastruct tubing using a 0.020 inch styrene shim wrapped around the pipe.

HO Scale Gate Valves

This laser cut multimedia kit makes seven ( 7) HO scale model gate valves for the gas burners and cold blast main of the Walthers Blast Furnace model. The 4 smaller gate valves (approximately 0.31 inch diameter pipe) are designed to fit the gas burner pipes, one is an extra to use as you see fit. The 3 larger valves are sized to fit 1/2 inch tube for use on the cold blast main. Since the kit does not include cold blast pipes, the builder must provide them.

One kit has enough valves to detail one Walthers Blast Furnace. The extra valve can be used as a spare, freight car load or installed on another industry as gate valves are common.

To purchase with Paypal

HO Scale Goggle Valve 3D Printed $12.99

HO Scale Goggle Valve Laser Cut $6.99HO Scale Gate Valves $29.99

What is a goggle valve?

In a blast furnace there is a need to control flows of high temperature and dirty, dust-laden gases. A goggle valve is a type of large industrial valve designed for this type of use. They are another signature item on a blast furnace.

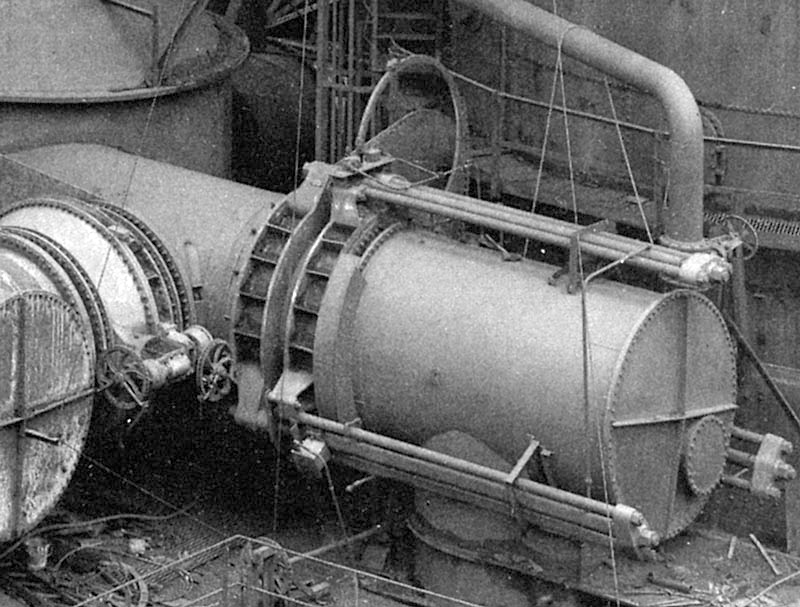

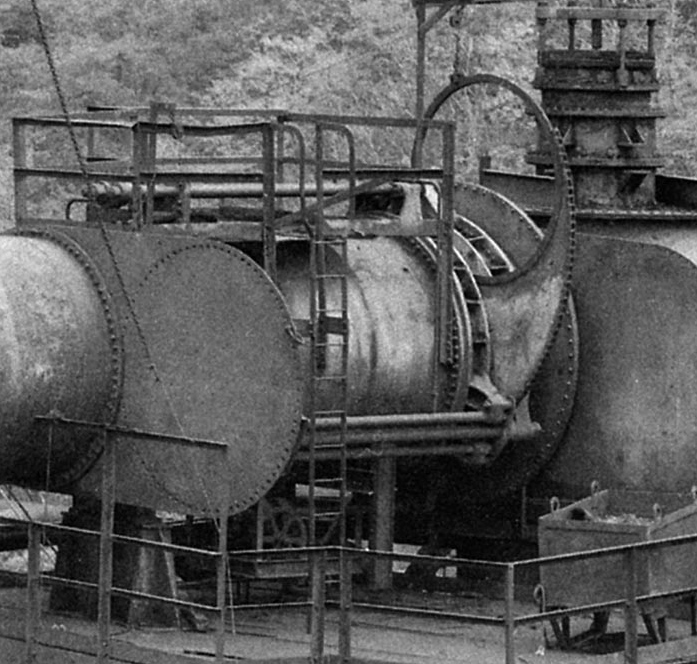

Goggle valves earned their name because the valve plate has two equal circular areas each defined by a sealing ring on both faces of the plate. One circular area is solid and the other is completely open. These two adjacent circular areas resemble a giant pair of eye-goggles. When the solid area is across the valve passage, it blocks the flow of fluid through the valve, and when the open area is across the valve passage, fluid flows freely through the valve. There is no intermediate position. It is either open or closed.

To actuate the goggle valve is a two-step operation. First, a section of the valve body moves in an axial direction to unclamp the goggle plate. This movement is quite small, on the order of a fraction of an inch or so, just enough clearance to allow the goggle plate to move in its housing. Then the goggle plate moves. In older designs it rotates on an arc. That is the type modeled in this kit. The valves body then moves axially back to clamp the valve and seal the perimeter of the openings.

On blast furnaces the valve body is usually exposed to the atmosphere, since small leaks during opening and closing are generally not a problem. This makes the mechanism highly visible. However, in chemical plants, goggle valves are encased in a bonnet to capture any leakage during the actuation.

Goggle valves have two main advantages. First they tend to be compact and can fit in tight confines, though on a blast furnace this is not normally an issue. Secondly, when open, the valve presents a smooth surface to the gas flow. Other valve designs, such as a gate valve, tend to have a valve seat. In a high volume flow with hot dirty gases, the valve seat can cause cavitation, a kind of a bubbling turbulence, which wears away the valve seat and requires expensive maintenance. On the other hand, goggle valves tend to be more expensive to initially install than other types.